About AAC

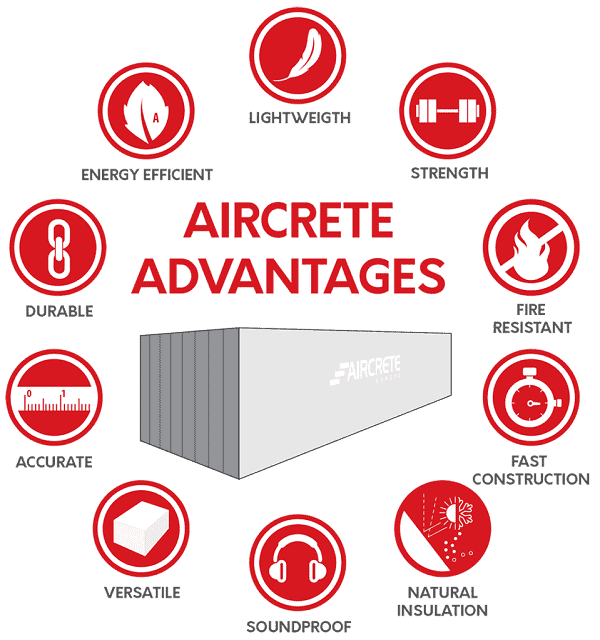

WHAT IS AAC AND BENEFITS OF AAC

What is AAC (Autoclaved Aerated Concrete)?

Autoclaved Aerated Concrete, also known as AAC or aircrete, is a green precast building material present in the global market for over 70 years and is extensively used in residential, commercial and industrial construction.

AAC is a well-established building material, which has rapidly gained worldwide market share from conventional building materials because of its superior characteristics.

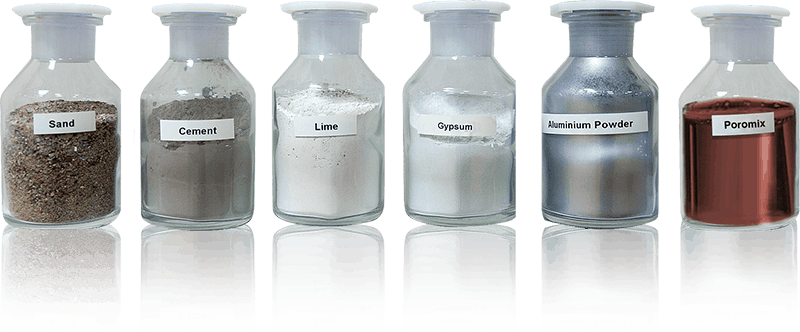

This eco-friendly building material is made from natural raw materials such as sand (or fly-ash), cement, lime, gypsum, aluminium powder and water. This mix creates an aerated concrete providing insulation, structure and fire protection in one lightweight product.

Click here to find more about the AAC production process.

Thanks to the air pores in the material, AAC is a great sound and thermal insulator. The thermal conductivity (λ) values are between 0,08 – 0,16 W/(mK) depending on density used.

AAC product densities vary between 300-800 kg/m³ and compressive strength is in the range 2,5 – 6 N/mm², making it extremely resource efficient material.

AAC panels offer new possibilities for product applications beyond AAC blocks. In panel based systems, installation of prefabricated elements is fast and easy. As a result, the total cost of an installed m2 is reduced compared to traditional building methods.

The SUPER SMOOTH surface of the panels adds to quick finish as the walls are ready for direct painting.

The large size of elements also allows for faster building and reduction of installation materials and labor. For example, one standard partition panel (60cm x 300cm) is 1,8m2of wall, equivalent to 12 standard AAC blocks (25cm x 60cm). An industrial panel can even have a surface of 6m2 per element (800cm x 75cm).

All AAC products are well-suited to withstand fires, earthquakes, and other natural disasters.

AAC achieves the highest possible level of fire safety and can withstand up to 4 hours of direct fire exposure. It is non-combustible and classified as Euroclass A1.

The lightweight, load-bearing structure and high compressive strength of AAC also contributes to be the perfect building material in earthquake and hurricane prone regions.

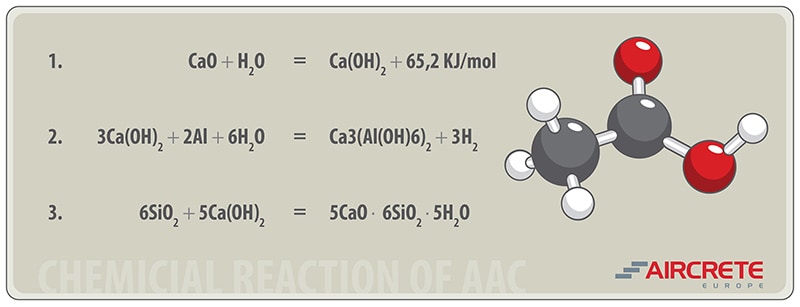

AAC COMPOSITION

Autoclaved Aerated Concrete consists of the unique combination of Tobermorite 11A molecules and air pores. Tobermorite 11A is a molecule that, once created, cannot physically decompose through heat, rot, corrosion or other chemical process and thus is very durable.

AAC products are produced using a mix of generally abundant-available raw materials like sand, cement, lime and gypsum. The raw materials are mixed with water, a very small amount of aluminum powder is added, and poured in large moulds.

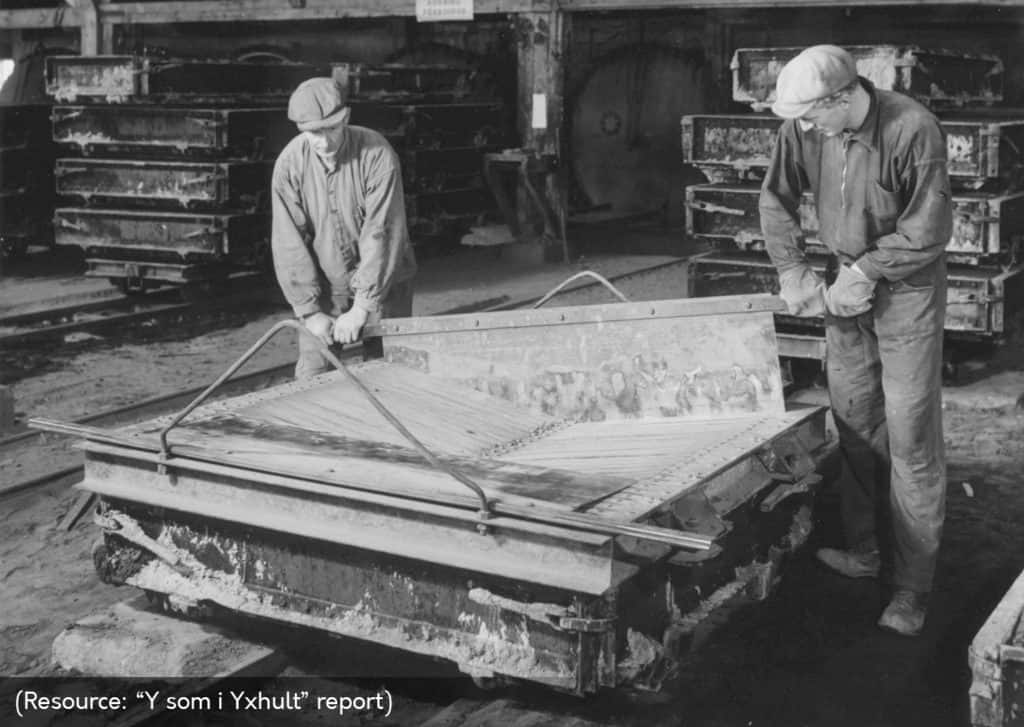

THE HISTORY OF AAC

Autoclaved Aerated Concrete as a building material has been industrially produced since the beginning of the 20th century. In the section below you read about the relatively short history of this long-lasting building material. The extended version of the “History of Autoclaved Aerated Concrete” article can be found in an expert article published in our download section.

Early days

First developments in autoclaved aerated concrete history are based on a series of process patents. In 1880 a German researcher Michaelis was granted a patent on his steam curing processes. Czech Hoffman successfully tested and patented in 1889 the method of “aerating” the concrete by carbon dioxide. Americans Aylsworth and Dyer used aluminium powder and calcium hydroxide to attain porous cementitious mixture for which they also received a patent in 1914. Swede Axel Eriksson made a serious next step towards developing modern AAC when in 1920 he patented the methods of making an aerated mix of limestone and ground slate (a so-called “lime formula”).