Aircrete Building System

A CONSTRUCTION METHODOLOGY

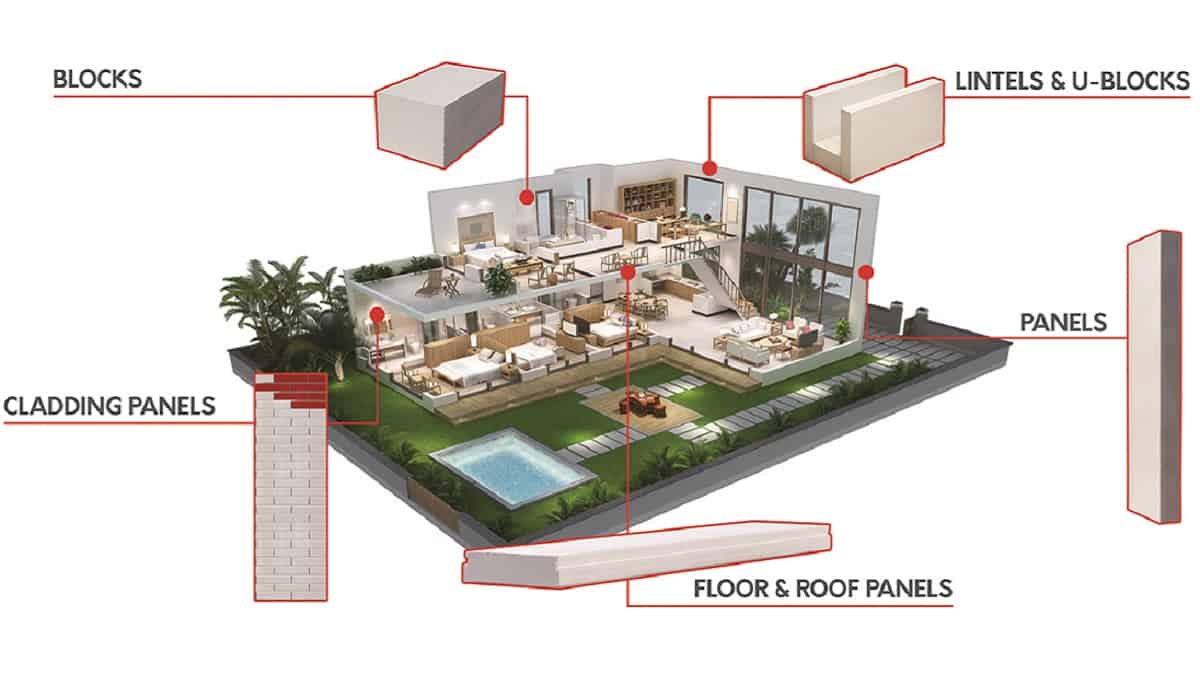

Aircrete Building System consists of standard-sized panels of different use; such as floor panels, load-bearing wall panels, roof panels, partition panels, cladding panels and lintels. Precise product dimensions, ease of handling and lightweight contribute to Aircrete Building System, resulting in direct time and cost savings in construction.

Building technologies and infrastructure systems improve continuously along with the growing need for cheap and efficient construction. Aircrete Europe applies a unique industry approach and supports the AAC producers in customizing their plant to manufacture a full scope of prefab elements for an integrated building solution. We help in designing new solutions or converting existing building projects into an optimized AAC building system.

Aircrete Building System is fully supported and powered by our production engineering solutions, making sure that every plant can manufacture the complete range of Aircrete Building System elements needed to assemble the designed building.

Do you have a new design project with AAC? Do you want to convert an existing building project into an optimized AAC building system? Contact us now.

Modular-type construction with AAC panels using Aircrete Building System (ABS) allows faster building, reduction of installation materials and labour. Here is why:

- ABS is applicable to any type of building, covering all variables at the local climate zone and seismic activity

- AAC producers work directly with their end-users enabling simplified construction process.

- The optimal cutting sizes determined in the project drawings minimize waste levels in the AAC production process, resulting in lower costs

- All prefab building materials come from a single source. This one-stop-shop concept simplifies purchasing and transportation processes on the construction site

- All elements arrive on-site is waste-free, there is no need for cutting on-site

- Large-sized AAC panels are easily installed, minimizing labour costs and construction times

- The SUPER SMOOTH surfaces of the panels enable a fast and economic finishing

- The total light weight of the complete building positively affects the foundation works

- Improved thermal homogeneity of the building contributes to better microclimate and comfort inside living and working spaces

RESIDENTIAL

The Aircrete Building System has a unique proposition in residential applications, whereby – when building up to 4 stories high – it can provide a full panel-based solution, eliminating all other structural building materials like traditional concrete columns.

For high-rise buildings, partitioning and cladding panel applications allow for a faster realization of the construction project due to the lightweight and accuracy of the material.

In addition, the use of AAC allows for an overall lighter structure, resulting in additional savings on the (steel or concrete) structure of the building and lighter foundation requirements. AAC cladding panels can also perfectly complement existing building structures, like a steel or wood frame building, whereby the AAC panels are used as a non-combustible, insulating panel providing comfort and safety to the living environment.

INDUSTRIAL & COMMERCIAL

For industrial and commercial applications, AAC load-bearing panels can serve as an all-in-one wall structure, eliminating the need for multiple layers of different building and insulation materials. Wall panels can be horizontally or vertically applied and be fixed to existing wood, steel or concrete columns.

AAC based walls, floors and roofs are the number one choice of construction material for many industrial warehouses and commercial shopping centres, driven by increasingly stringent fire regulatory requirements and an overall reduction in delivery time of the construction project.

Besides, all elements in Aircrete Building System perform superior thermal and sound insulation capabilities. These qualities deliver outstanding benefits to builders, developers and designers for any project that range from low-rise industrial and commercial developments to high-rise constructions.

PRODUCT SPECIFICATIONS

Aircrete products meet the most requirements of building standards and rules, offering a wide range of innovative, efficient, durable and sustainable solutions for works of any size.

Learn more about the variety of Autoclaved Aerated Concrete (AAC) products made in AAC plants using technology from Aircrete Europe:

INDUSTRIAL PANELS

• Standard length of up to 6 meters

• Easy and fast installation

• High load-bearing capacity

• Perfect solution for industrial firewalls

ROOF AND FLOOR PANELS

• Standard length of 4 – 6 meters

• Thickness up to 30cm

• Customized profiled side edges

• Easy and fast installation

PARTITION PANELS

• Standard length from 2.4 to 3 meters

• Easy drilling, sawing and nailing

• Time and cost efficient installation

• SUPER SMOOTH surface

CLADDING PANELS

• Standard length of 2 meters

• Customized surface design

• Extra heat insulation layer

• Direct installation on concrete/steel structure

STRUCTURAL BEAMS

• Length up to 3 meters

• High load-bearing capacity

• SUPER SMOOTH surface

• Installation on AAC/concrete/steel structure

BLOCKS

• High level of dimensional accuracies (<1mm)

• Flexibility and freedom in interior design

• Easy application for non-load bearing structures

• Great alternative to brick masonry

GALLERY