Efficient energy utilization is a crucial theme in any type of industry and companies a forced to optimize their utility consumptions based on socially responsible indicators, as well as financial pressures due to the rising cost of energy and natural resources. Also, the international AAC industry has to make an improved shift towards recycling and optimal use of energy for existing and new build plants.

Environmental aspects are a high priority for Aircrete Europe resulting in a strong focus on energy-efficient engineering, recycling and fossil fuels reduction in our plants. Aircrete process engineers have dedicated the last months to an extensive and renewed analysis of the energy use in our plant process to develop the Aircrete Energy Model.

With an empirical analysis of heat transfer between the autoclave and the surroundings, a breakdown of the energy requirements for every individual component for autoclaving has given us a renewed insight of the exact requirements of the energy in the plant. Furthermore, we have defined optimal thickness for insulation for different geographical areas. The Aircrete Energy Model simulates condensate generation and heat flows, as well as different configurations of pressure for the condensate recovery lines in order to determine the amounts of flash steam and heat available for reuse.

Furthermore, a technical evaluation of different equipment for the re-utilization of waste has been included in the Energy Model. The results of the model can provide us with the best and most economically feasible solution that maximizes the energy utilization per customized project.

The renewed Aircrete Energy Model shall provide the following advantages to our international partners:

- Effective utilization of all the heat in the process, from optimal steam distribution to excellent condensate reuse that can lead to savings up to 45% in natural gas consumption.

- Optimal insulation to minimize the heat loss and maximize the savings in an autoclave, taking into account your specific case and location.

- Savings in energy without compromising plant capacity.

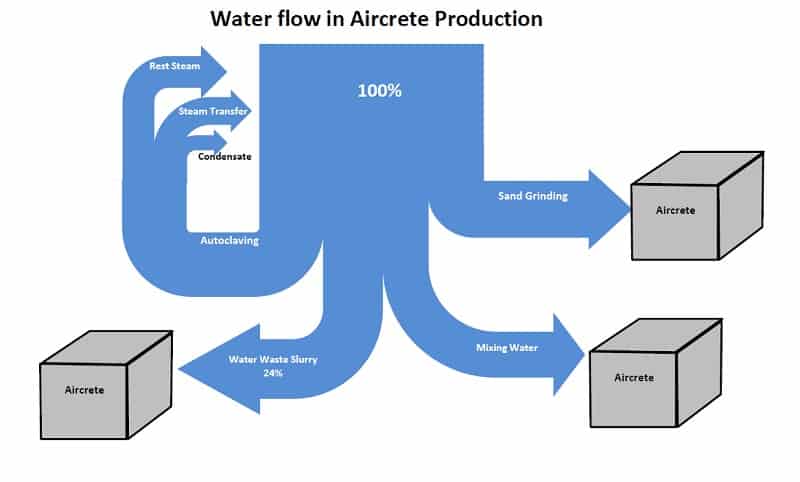

- Efficient water management in the plant reducing the residual water almost to zero.

- Waste heat can be transformed to extra services such as green air conditioning and heating.

The above-mentioned engineering development contributes to a greener and more efficient AAC production. Optimized resource consumption results in turn in significant cost savings and increases the competitiveness of the plant. The figure below illustrates an overview of the water recycling allocation to various process locations of our plants: