The primary objective of all production managers, regardless of their industries, is reducing production costs while optimizing the product quality at the same time. The AAC industry is no exception, the goals are the same. However, for AAC production, not only the right technology is critical, but also the production process know-how is a vital aspect in mastering the best quality and efficient AAC production.

It is important that AAC production managers have a clear insight on the drivers of metrics and the potential improvement areas of the factory, if they want to optimize the quality of the product and control the operational process-related costs. Well-maintained equipment is likely to contribute to consistent quality and availability of the plant, however new technology innovations, flexible capacity extension, optimized cycle times and reducing bottlenecks will further enhance and optimize AAC production and achieve the desired goals. In addition, optimizing the production process by looking at the raw material quality, formula optimization, waste reduction and customized machinery refurbishments can have a significant positive impact on product quality and cost optimization.

In order to fully understand what drives product quality and operational costs, it would be advisable to have an independent technology partner to perform a “scan” of the factory. The advantage is that this allows for a new look at the plant, from a different angle, from a partner that has been to many plants around the world and brings fresh ideas to the table. This would help to identify where possible improvements on both the technology and process side could be realized per production area. Based on the result of such a plant scan, a detailed report with an action plan should indicate how to realize those production and cost optimizations, sometimes with only minimal adjustments in the production process and at only minimal capital investments.

Common issues with existing AAC plants

AAC plants often face similar challenges in their facilities – especially if the plants are equipped with older production technology – such as:

• Overall challenge to improve product quality

• High level of white waste

• Slurry dilution

• Not achieving a homogeneous mix

• Excessive product damage at the cutting line

• Excessive product damage at the unloading line

• Autoclaving process issues, resulting in quality issues

• Raw material issues

• Unable to achieve the designed output volume of the plant

• Inability or difficulty to expand product portfolio (e.g. to make super smooth panels)

• High labor costs

• Safety issues

• Logistics problems with raw material, packing and/or distribution areas

One of the main goals of Aircrete Europe is to help AAC plants around the world run more efficiently, become more productive and improve their product quality. Many years of experience in servicing and upgrading plants brings a different viewpoint to the challenges every manufacturer faces. As many of the innovations we brought to the AAC industry, we have developed a solution called Aircrete Plant Scan.

Benefit from global best practices on how to optimize AAC production

As implied by its name, Aircrete Plant Scan targets to examine a plant to provide insights and valuable recommendations about the issues the facility faces. These performance and improvement outcomes of a plant scan include but not limited to:

• Product quality improvements

• Operating cost reductions

• Production output optimizations

• Safety enhancements and workforce risk reductions

Specialized in the field of AAC technology – particularly related to AAC panels – Aircrete Europe has an embedded deep knowledge of the production process in its organization. The outcome of an Aircrete Plant Scan visit by two experienced professionals assists plant managers to improve their operations.

Insights and recommendations

The results of an Aircrete Plant Scan could be anything related to the process or the machinery. In some cases, the advice could be a further examination of a specific area by another specialist. Based on this detailed check, a components replacement proposal can be prepared as a next step. In some other cases, the installation of additional equipment or completely new machines could be the result of a plant scan. Sometimes it also relates to a piece of advice on how to make organizational improvements on the operations and the maintenance process. The replacement of the slurry pump to prevent slurry dilution, installation of density loops with load cells for an automated recipe adjustment and replacement of the cutting line to have Super Smooth product surfaces are just a few project samples that were realized after a plant scan.

Going through an Aircrete Plant Scan is just like going through an independent audit undertaken by an industry expert. As Aircrete Europe not only has decades of experience in the industry, but also operates its own plants, it ensures that they are the optimal technology partner for such an audit, hereby not only looking at plants with Aircrete equipment installed.

The following case studies are good examples of how conducting an Aircrete Plant Scan resulted in distinct results to optimize AAC production for these AAC manufacturers.

Case Study 1

The Customer

A large producer of concrete precast elements for road, electric and water infrastructure, as well as for building the commercial, logistic and production facilities in Romania. Aircrete Europe was welcomed to run a plant scan to address slurry density issues.

It was hard to keep the slurry density under control through manual measurements

The Challenge

Keeping the slurry density variation under control consistently was a major issue for the client. The measurements were executed manually by hand. The existing automatic controller was already shut down because it was not working properly.

The Solution

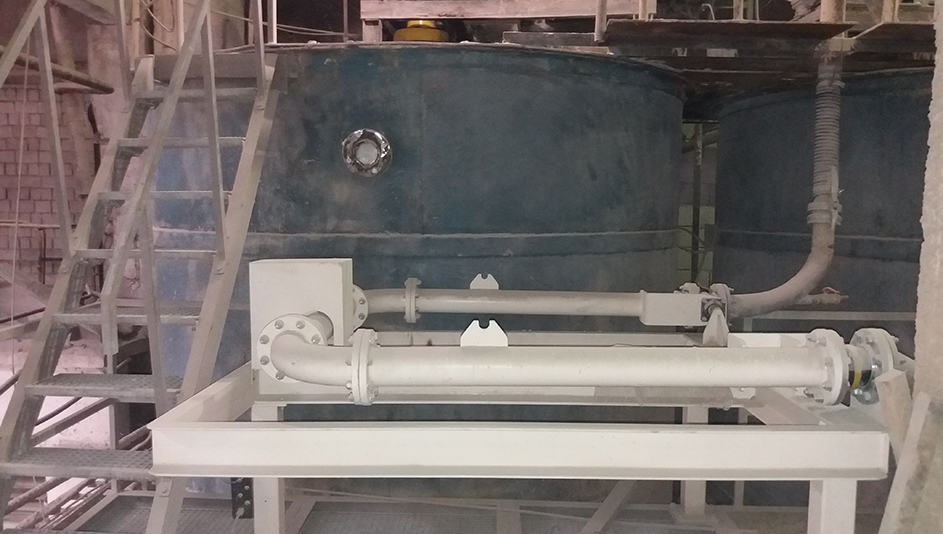

Aircrete Plant Scan report recommended a load-cell based u-pipe system that would be integrated with the mixer control system.

The u-pipes installed after plant scan are integrated with the mixer control system

Results

Three u-pipe systems were installed to measure the fresh slurry, the return slurry and the cutting-pit slurry respectively. The accuracy of the process has drastically improved through automation and the formula changes automatically depending on actual measurement results.

Case Study 2

The Customer

A leading building materials and construction solutions company in the UK. The AAC production plant technology is from the 70`s. Aircrete Europe team was invited to define the areas to bring up-to-date on a general scale through a plant scan.

The old gripper on the unloading line was not able to hold new products

The Challenge

For around 40 % percent of the products, the existing gripper on the unloading line was not ideal for the new pack dimensions and caused high down-times

and damage to the products. The gripper needed to be modified to be able to fit the same products on different-sized pallets.

The Solution

Aircrete Plant Scan report recommended an engineering assignment including a motor replacement of the gripper so that it can pick both the old and new sized pallets up.

Replacement of the gripper after plant scan enabled heavier products to fit on the pallets

Results

The customer received a detailed engineering rework plan with indicative budgets so that they can choose among options from different solution providers. In the end, the project was outsourced to Aircrete Europe and was delivered in a couple of weeks.

Case Study 3

The Customer

A producer of blocks and panels in South East Asia, that owned a Hebel Flat-Cake system from the 90`s. Aircrete Europe specialists were invited to conduct

a plant scan to provide insights on what can be improved in the facility.

The cutting line was not suitable for products with 5 mm incremental thicknesses and super smooth surfaces

The Challenge

The existing technology was outdated for the new product portfolio they wanted to make with 5 mm incremental thicknesses and super smooth surfaces.

The Solution

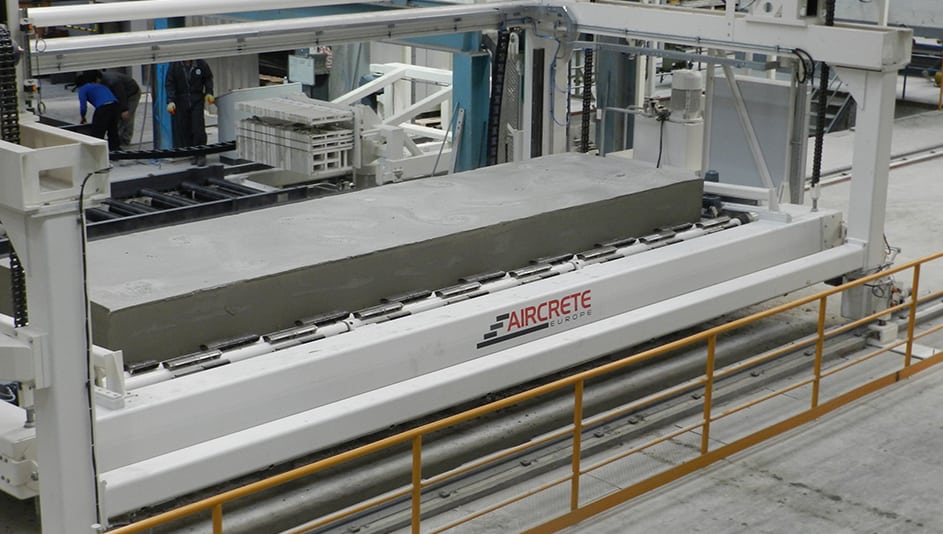

Aircrete Plant Scan report recommended the replacement of the whole cutting line while not having to change the existing plant infrastructure at all.

The new cutting line was successfully integrated with the plant’s existing infrastructure

Results

As the customer gained trust and felt confidence with Aircrete Europe`s approach and staff, the implementation of the new cutting line was realized shortly. The project was executed with a detailed engineering work to keep the infrastructure changes at zero level. The relationship that started with Aircrete Plant Scan turned into a full-scale modernization of the plant. The second phase of the project involves a capacity increase, further plant automation, additional technology supply and continuous support.

Ready to optimize AAC production? Order your Aircrete Plant Scan now:

If you are looking for additional knowledge transfer and consulting to improve your AAC plant performance, please contact us now by filling in the form below: