Construction markets in South East Asia are still growing fast, with an increased focus on green and efficient construction with minimal waste using prefabricated elements. The Aircrete Building Solution, based on the prefab Aircrete AAC panels, allows for zero-waste construction sites. Besides, AAC plants with Aircrete technology support sustainability by producing virtually zero-waste in the production process. That is why Aircrete AAC production technology is just the right choice to make high-quality AAC panels that are an integral element of the prefab, modular-type construction.

“Zero-Waste Cities” pilot project

Recently, China is taking bold steps in tackling environmental pollution and protecting blue skies, clean water and soil. In January 2020, the Chinese State Council launched a work plan for the “Zero-Waste Cities” pilot project. 11 cities have been selected to develop comprehensive management systems for different types of waste streams. Encouraging the minimum generation of construction and demolition waste is among this work plan to achieve green, low-carbon and circular development.

Construction waste is a major source of solid waste. Thousands of tons of solid waste is produced every year from building sites. Therefore, minimization of construction waste has become a pressing issue, as already underlined by the work plan of the “Zero-Waste Cities” pilot project in China. Since adopting prefabrication in construction minimizes construction waste on-site, the Chinese government has introduced stringent measures to facilitate the prefabrication.

Aircrete Building System is a construction methodology that uses a full scope of standard-sized AAC panels such as floor panels, load-bearing wall panels, roof panels, partition panels, cladding panels and lintels. Aircrete Building System is a Lego-ised building solution with highly standardized panel elements. Because all elements of the building are prefabricated at the factory level, they arrive on-site with exact dimensions. This eliminates the need for cutting on-site, therefore preventing the formation of construction waste before all else (Fig. 1 &2).

Fig. 1 &2: Zero-waste construction sites are achievable with Aircrete Building System as all elements of the building are prefabricated at the factory level and they arrive on-site with exact dimensions.

As a unique industry approach, we support the AAC producers in customizing their plant to manufacture a full scope of prefab elements for Aircrete Building System. We help in designing new solutions or converting existing building projects into an optimized AAC building system. our production engineering solutions team fully supports and empowers the Aircrete Building System, making sure that every plant can manufacture the complete range of Aircrete Building System elements needed to assemble the designed building.

Recent Aircrete activities in South East Asia and China towards Zero-Waste Construction

“Providing greener, faster and better building technologies for the world of tomorrow” is our mission. Aircrete Building System that contributes to zero-waste construction is an inseparable part of this mission. With this target in our mind, our subsidiary, Aircrete China became official and active members of the China Aerated Concrete Association and Wall Reform Committee. Both institutions have a big impact on the “Zero-Waste Cities” project that adds up to China’s State Council initiative towards green prefabricated buildings.

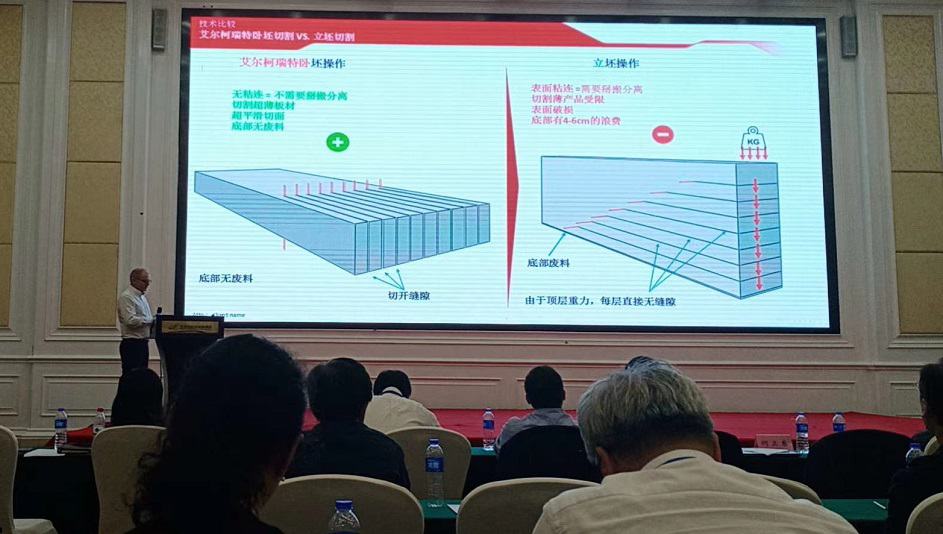

Consequently, our teams both in China and the Netherlands had quite a busy agenda in September. We participated in the Wall Reform Committee`s conference (physically) in Changsha City, Hunan Province. The event hosted 200 participants related to the AAC industry. Aircrete China`s General Manager Andre Antonow`s presentation was in the focus of great interest (Fig. 3). Our paper published in the event`s conference book detailed how Aircrete flexible mould technology facilitates zero-waste in AAC panels production process. We also trained over 200 industry professionals on Aircrete Building System and AAC Wall Panels and their impact on the “Zero-Waste Cities” project in China.

Fig. 3: Aircrete China`s General Manager Andre Antonow`s presentation in the Wall Reform Committee`s conference

In addition, we participated in two webinars organized by Netherlands Enterprise Agency (RVO). Our first pitch in the “Recycling and zero-waste in Chinese construction” webinar covered the details on AAC panels help achieve a greener and more sustainable future in construction. Our presentation video can be reached on this link. The second event was a live interview in Den Haag with our Managing Director, Ralf Beier as a part of the China Business Week. Ralf explained how the Aircrete Building Solution, based on the prefab AAC-panels, allows for zero-waste construction sites and why AAC plants with Aircrete technology support sustainability by producing virtually zero-waste in the production process. A recap of this interview and Q&A session is accessible here.

Get in touch with us

Do you have a new design project with AAC? Do you want to convert an existing building project into an optimized AAC building system? Contact us right away: